Assuming each brake is a disc brake with mean radius of 10 inches determine normal brake. F coefficient of friction.

1- The force analysis begins with floating lever 5 because it receives the applied force F.

. Mechanics and Machines Calculations Menu. The moment M f of the frictional forcef𝑁 about the hinge pin at A is. Intent Design is a global technology enterprise providing product engineering design and.

The validation of design is done via calculations as well as. The solution should be applied with low pressure to prevent dust from becoming airborne. Depending on the position of rotor the braking system is of two types - Inboard Braking System and Outboard braking system.

Heat Generated p Ac f V 778 Btumin Where. In an Inboard braking system the rotor brake disc. Force on each brake drum F4 36449 N Area of the shoe brake in contact with brake drum 2 9423 30 106 565 103 Pressure on the brake drum FA 3645 565 103 0645 MPa To calculate the stress in the Brake Drum by the application of pressure.

VEHICLE DATA REQUIRED FOR CALCULATIONS GVW -Laden Front Axle weight Kg if provided 12592 Calculated 12592 Rear. The paper presents methodology of design various considerations made during design and the logic behind them. 41 Model of Disc Brake.

Fig3 Two shoe drum brake The free body diagram for all the components of the two shoe drum brake can be shown in figures 3-b to 3-f. Compared to a brake rotor a drum has significantly less contact area shown in Figure 12-5. For brake disc and its design plays key role in design of braking system of vehicle.

Patented a design for a disk brake in 1902 in England. Drum brakes depending on certain advantages discussed below. A drum brake is a brake that uses friction caused by a set of shoes or pads that press against a rotating drum-shaped part called a brake drum.

Br sinθ max θ 2 sinθ r c cosθdθ θ 1 𝐱. The drum is stopped by the motor and the balloon held by two fail-safe brake systems. These early disk brakes were not as effective at stopping as the contemporary drum brakes of.

If the load is at rest the static brake. Determine stopping force required. Double Shoe Brake.

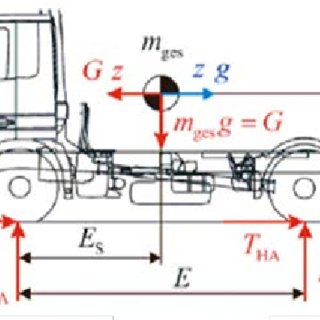

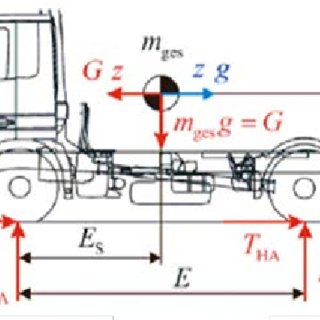

Design requirements R BRAKE FORCE AT FRONT BRAKE FORCE DISTRIBUTION DIAGRAM UNLADEN CONDITION LADEN CONDITION. CALCULATION TBOF DISC BRAKE. It was incorporated into.

The brake design calls for it to be able to stop in 400 feet. Brake Calculations There are many books on brake systems but if you need to find a formula for something in particular you never can. Ac contact area in².

Intent Design Pvt Ltd. Produced between 1906 through 1914. Distribution Analysis of Aluminum Composite and Cast Iron Brake Drum Using Ansys International Journal of Emerging trends in Engineering and Development 2012 Vol.

Brake factor computer software input and out put diagrams are illustrated for a typical S-cam-brake design in Figures 2 and 3. 31 Braking Force and Torque Calculations 18 32 Floating Disc Selection 19 33 Floating Disc Buttons 20. Drum diameter reel diameter etc The brake will need to overcome this load before it can start to slow down the machine.

Maximum brake force calculations for Drum Brakes Anirudh L Subramanyam Sandeep Banik The maximum brake force that can be generated on application of drum brakes are a. The green line represents the total brake factor of the leading-trailing S-cam brake. M f fdN r ccosθ fp max.

The equations needed to design a braking system are not difficult to derive but this page is a reference to most of them. 312 Chapter 12t Drum Brake System Principles are used when working on the brake system. P average contact pressure.

Determine stopping torque required if wheels are 36 inches in diameter. Phosphate water-based detergent to wash the brake drum or rotor and other brake parts. Use shims to adjust differences in height between brake and brake drum if necessary.

Internal Drum Shoe Brake Design Equations. The calculation for the heat flux is done by the relations given in the brake design and safety by Rudolf Limpert. 3 Design Manual for Winch Systems Design basis Nomenclature Design basis Lifting load m h t Lifting speed v hmmin Lifting height H m Number of fixed deflection sheaves between drum and hoist or moving part n u - Required service life t h Number of winding layers on a drum n l - Number of parallel hoists or ropes reeved on a drum n.

The winch is driven by an electric motor through two reduction gear stages. V peripheral velocity of drum. Disc brake is the recent trend in automobile vehicles which dissipates the heat faster than the conventional drum.

The wheel hub and brake assembly components should be. Taking moments about O 25 establishes 2- For the link 4 but in opposite direction. If the thickness to diameter ratio tD ratio.

Modify the design based on the field test results. WHEEL CYLINDER Wheel cylinder or caliper pistons. In view of above after mounting the brake on the brake drum heed the following instructions to center height and centering must be within 025 mm the brake to the brake drum.

Basis of Brake Calculation Basic braking calculations are derived from simple. It is assumed that the out of balance opposes the action of the brake. 𝟒 𝐢 𝛉 𝐱 𝟒 𝛉 𝛉 𝛉 𝛉 The torque applied to the drum by the brake shoe is the sum of the.

For example for a lining-drum friction. Insert mounting bolts into the mounting base but dont tighten them yet. Important to understand action force and friction force on the disc brake new material how disc brake works more efficiently which can help to reduce the accident that may happen in each day6 IV.

Allow the solution to flow between the brake drum and the brake support or the brake rotor and caliper. Brake design plays an important role in heat transfer like. DRUM BRAKE SYSTEM F ma.

Either brake is capable of holding the balloon independently. A motor brake is fitted to the drive motor and a hydraulic brake acts directly on the drum disc flange. Most of the vehicles use hydraulic braking system while some light vehicles such as bicycles use brake wires.

The term drum brake usually means a brake in which shoes press on the inner surface of the drum. DESIGN CALCULATION OF DISC BREAK ROTOR Here presenting the work for disc brake of MARUTI Company for stress reduction studies. These procedures are discussed in Chapter 13.

Determine torque per brake assuming there are 10 sets of brakes. 3 Issn 2249-6149 pp 281-. R Brake drum the drum has an internal friction surface for the shoes to rub against.

PC-BRAKE FACTOR software computes the brake factor of many different drum brake designs.

Internal Drum Shoe Brake Design Equations And Calculator

Brake Design And Calculation Pdfcoffee Com

Pdf Optimization Of Design Of Brake Drum Of Two Wheeler Through Approach Of Reverse Engineering By Using Ansys Software Semantic Scholar

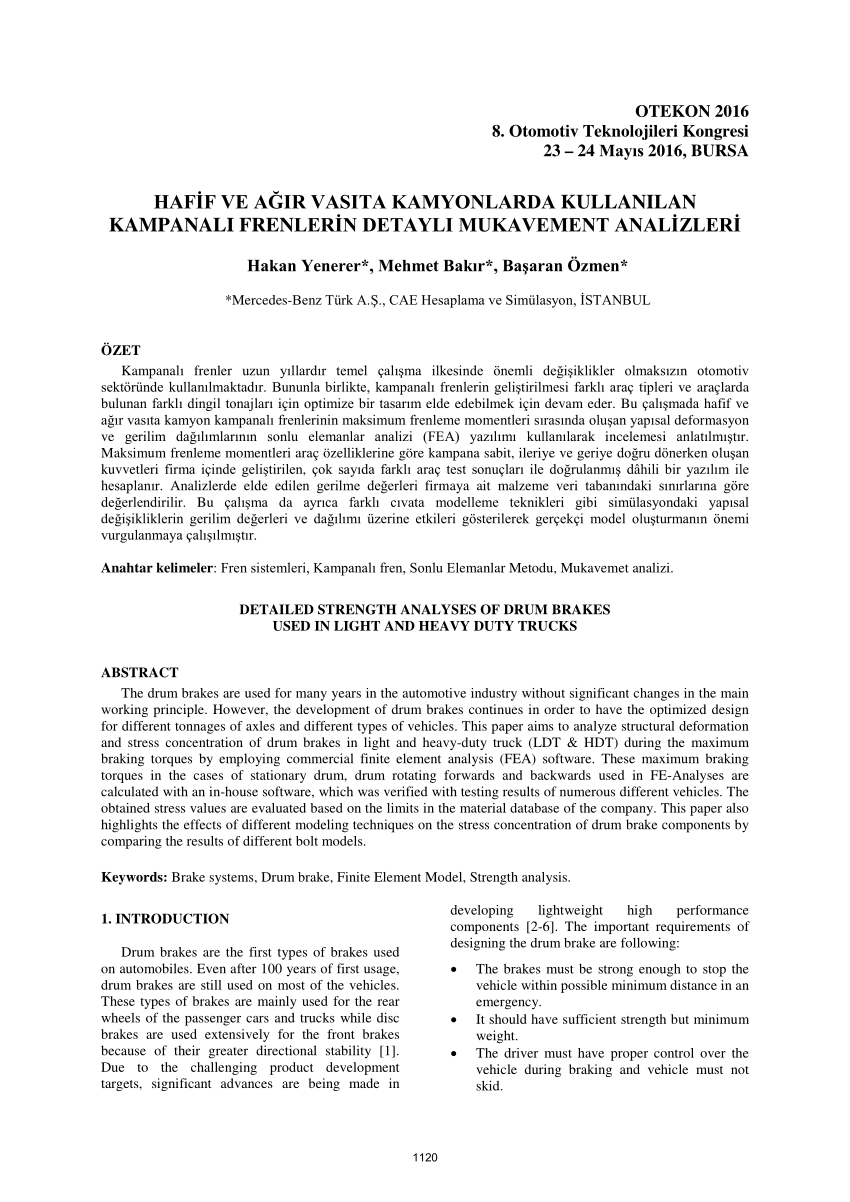

Pdf Detailed Strength Analyses Of Drum Brakes Used In Light And Heavy Duty Trucks

Drum Brake Calculation Pdf Brake Vehicles

Pdf Detailed Strength Analyses Of Drum Brakes Used In Light And Heavy Duty Trucks

0 comments

Post a Comment